ECG Cost Analysis

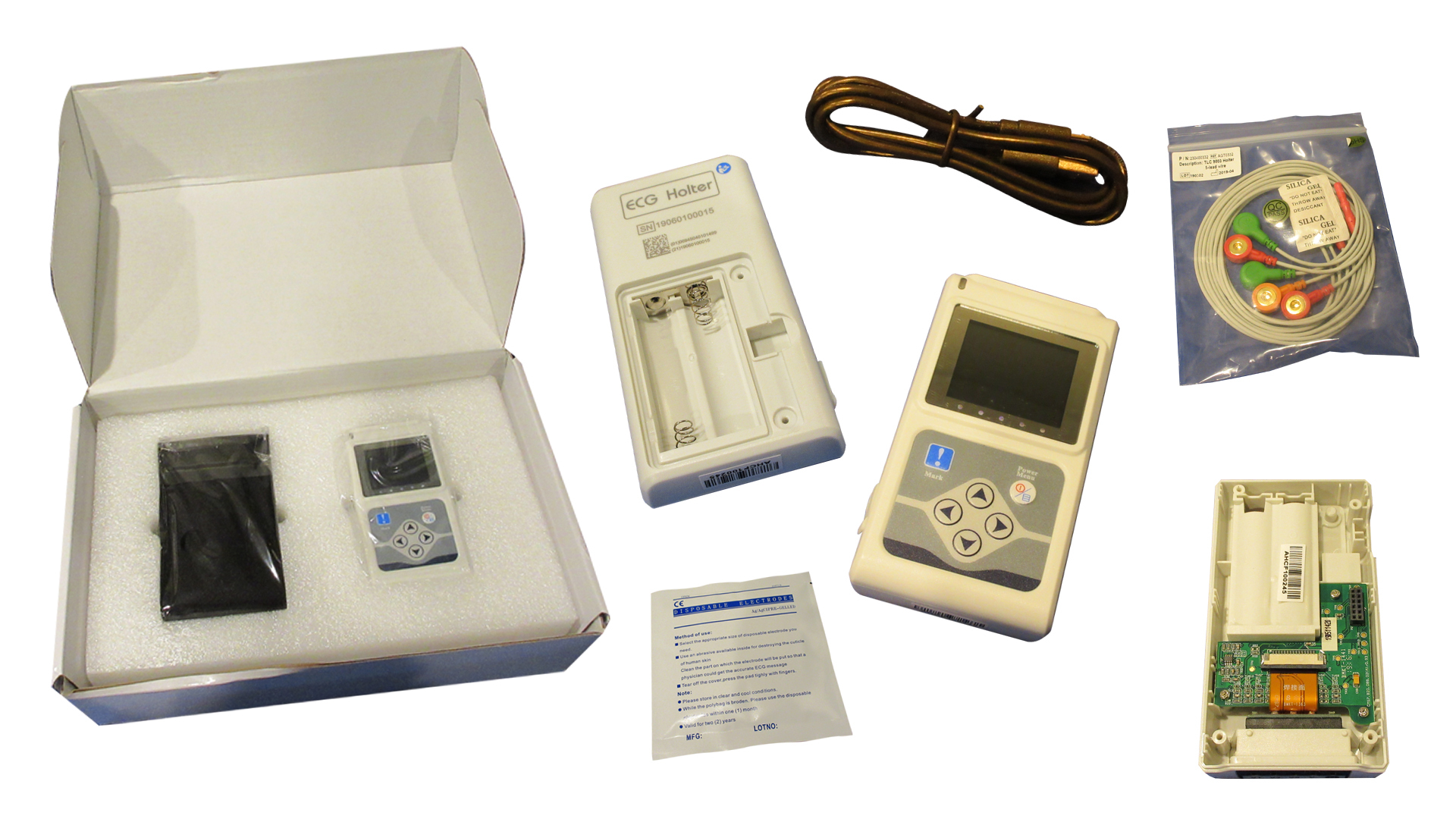

In our last blog post, we provided a teardown and cost analysis of a consumer-grade pulse oximeter. As another example of how we can apply our analysis methods to medical products, let’s take a look at the TCL5007 electrocardiogram (ECG), which detects the heart’s electrical activity to record heart rate and rhythm. A commonly used medical instrument, ECGs play a role in most medical offices.

OUR PROCESS

We take a forensic approach to cost analysis, breaking down and investigating each individual subcomponent within the product. Our investigation takes into account the cost of materials, transport, manufacturing process and more to determine the value of each subcomponent, and our methods focus on the actual physics associated with production and assembly. For example, when investigating the manufacturing process for an injection molded piece, we look at machine tonnage, cycle time and required clamping forces.

We repeat this process for every element on the device’s bill of materials. We also incorporate associated fixed and variable costs into our Intellicosting model, such as labor rates and scrap costs. When applying our forensic approach to the ECG, our analysis consists of both mechanical and electronic divisions.

MECHANICAL COMPONENTS

First, we completely disassemble the finished product and photograph and weigh each mechanical component. Our proprietary Intellicosting software requires information like material type, quantity of components, country of manufacture and physical dimensions. This software enables us to gain key insights into the costs of many manufacturing processes.

After receiving these inputs, the model accounts for capital, number of operators, scrap rates, raw material usage, raw material price, indirect labor, number out at each operation, burden, selling, general and administrative expenses (SG&A) and profit. Variable and fixed rates — such as the cost of labor in a country — are adjustable within the model.

ELECTRONIC COMPONENTS

Like the mechanical components, we remove all the electronic pieces of the ECG and photograph and weigh them, providing additional notes on design-for-manufacture concerns and the manufacturing process. Next, we categorize the components by individual boards, circuits and mechanical assemblies. Afterwards, we evaluate and apply our cost model to the components by function of passive, discrete, active, application-specific integrated circuit (ASIC) and custom components.

Additionally, we apply forensic physical delayering techniques or X-rays, to further extract die area and manufacturing information. To determine the manufacturing processes and material costs for coatings, potting, flex material and more, we examine each circuit board substrate material. We also consider design requirements, such as software, hardware design, mechanical design, testing, validation and systems, to determine costing. As with the mechanical costing, we investigate the manufacturing factors of capital requirements, labor, burden and SG&A with machine models to analyze cycle times and line layout.

FINDINGS

After this comprehensive analysis of the TCL5007 ECG, we determined that the total cost to manufacture each unit is in the $50-$60 range. The price for this device at a popular consumer-grade retailer is roughly $240.

Sign up for our monthly newsletter for more tips and information on how to reduce costs.